Instrumentation Cable In India - Construction:

Instrumentation Cable In India are single or multi-pair/triple components intended to convey signals. They are utilized for connecting instruments and electrical hardware particularly in plants where interaction control is required, where transducer-produced signals are communicated through to boards, controllers and different gadgets.

Twisting of the sets lessens electromagnetic interferences (EMI) from outer sources or cross talk internal sets/significantly increases. Instrumentation Cable Manufacturers In Delhi.

The development with individually protected pair is regularly utilized for simple signs and the development with generally speaking safeguard just is utilized for advanced signs. Instrumentation Cable Suppliers In Delhi.

Regular applications are in the process industry: Oil and Gas, Chemical and Petrochemical, Water treatment, Mining and all the more for the most part in any plant where a cycle computerization is carried out. Instrumentation Cable Exporters In India.

Construction:

Configuration:

Multi-core, multi-pair or multi-quad laid up concentrically or in units.

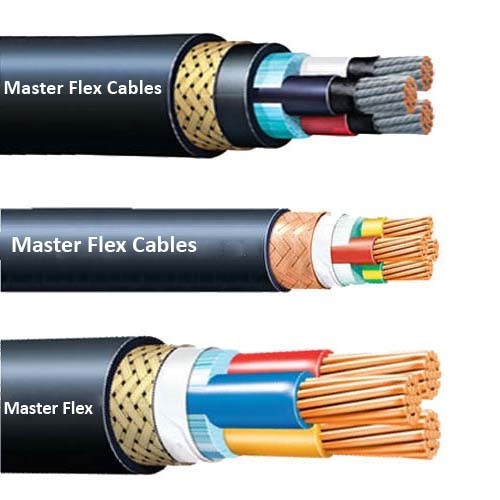

Conductor:

Solid or stranded, tinned, bare or silver-plated annealed, high conductivity EC grade copper, sizes ranging from 0.5 sq. mm to 2.5 sq. mm.

Insulation:

PVC, Solid PE or special thermoplastic materials, heat resistant PVC with an operating temperature range of 85ºC to 105ºC. Halogen free polymeric or elastomeric insulation may also be provided. Core identification through colour coding or character printing.

Core-Wrap:

One or more Plastic Tape

Screen Cores:

Pairs or Quads can be individually or collectively screened or both. Screening with Copper or Aluminium Mylar Tape, Copper Wire or Aluminum Wire.

Drain Wire:

Drain Wire of solid or stranded, bare or tinned copper wire normally provided with both individual and overall screening.

Mechanical Protection:

Cables can be armoured with galvanized steel wires and strips or double helical steel tape.

Inner & Outer Sheath:

PVC of Black or Grey colour. Heat Resistant, FRLS PVC Sheathing, Halogen Free Polymeric or Elastomeric sheathing also available.

Additional Features:

Communication Pairs, Bicolor Extrusion, Band marking can be provided on request. Designed to combat all the basic types of noise which affect process instrument signals namely static, magnetic disturbance, manmade noise and cross-talk. Reference specifications for testing are IS: 10810, ASTMD2863, ASTMD2843, IEC-754(I), VDE 0815, VDE 0207 (PT5), IEE383, SS-424-14-75 (F3), VDE0207 (Part IV), VDE0472, IEEE Transit No.467 and as per customer’s requirement.

Comments

Post a Comment